Introduction to ISO 8735 – 5×20 – A-C1 Entl.

In the world of industrial standards, the International Organization for Standardization (ISO) plays a pivotal role in ensuring uniformity and quality across various sectors. One such standard is iso 8735 – 5×20 – a-c1 entl., which outlines specifications for dowel pins, a crucial component in mechanical engineering and manufacturing.

Understanding ISO 8735 – 5×20 – A-C1 Entl.

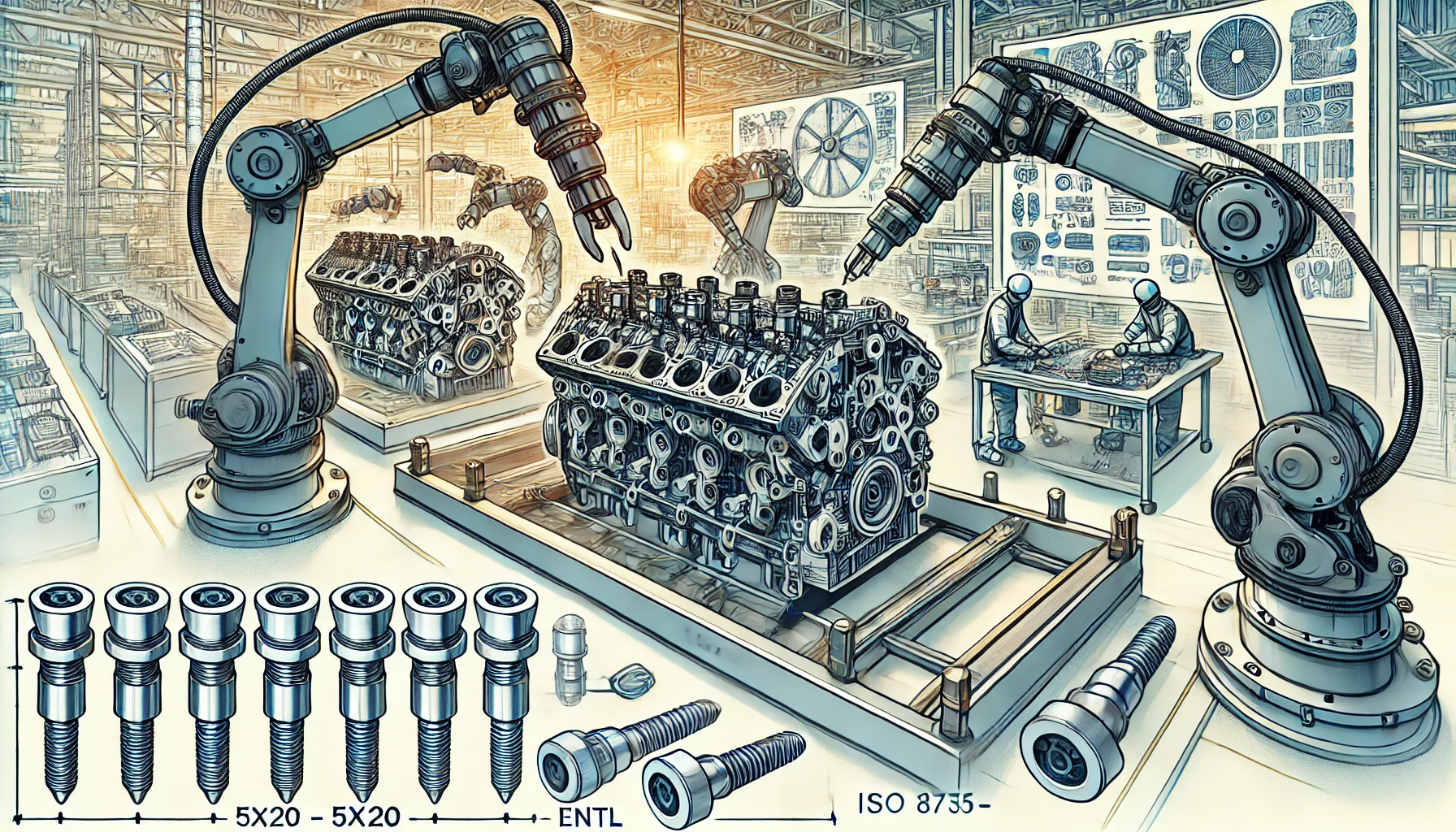

ISO 8735 defines the characteristics of dowel pins, primarily used for positioning and fixing two components accurately without hindrance to the assembly and disassembly processes. The specific notation “5×20 – A-C1 Entl.” refers to the dimensions and material properties of these pins—5 mm in diameter and 20 mm in length, with a particular composition and coating defined by ‘A-C1 Entl.’ This precision in specification helps ensure that the components fit seamlessly across universally standardized assemblies.

Significance of ISO 8735 – 5×20 – A-C1 Entl.

The significance of adhering to ISO 8735 with the specific parameters of 5×20 – A-C1 Entl. cannot be overstated. It provides mechanical engineers and manufacturers with a reliable standard that guarantees compatibility and functionality in diverse applications, from automotive to aerospace. This standardization helps in reducing errors in production lines, enhances the efficiency of assembly processes, and significantly cuts down on maintenance time and costs.

Integrating iso 8735 – 5×20 – a-c1 entl. into Manufacturing Processes: Enhancing Precision Across Industries

The Role of ISO 8735 – 5×20 – A-C1 Entl. in Modern Manufacturing

ISO 8735 – 5×20 – A-C1 Entl. details the specifications for dowel pins, which are pivotal in ensuring precision in the manufacturing process. These small, yet critical components are used extensively to align parts with exactitude, which is essential for automated assembly lines and high-quality production standards. The “5×20” specifies the pin’s dimensions—5 mm in diameter and 20 mm in length—while “A-C1 Entl.” indicates specific material and treatment criteria, ensuring the pins meet rigorous durability and strength standards.

Impact Across Various Industries

The adoption of ISO 8735 – 5×20 – A-C1 Entl. standards impacts multiple sectors significantly:

- Automotive: In automotive manufacturing, precision is non-negotiable. Dowel pins per ISO 8735 standards ensure that critical components like engine blocks and transmission assemblies are perfectly aligned, reducing wear and tear and increasing the lifespan of the vehicles.

- Aerospace: The aerospace market depends on components that may endure excessive conditions. ISO 8735-compliant dowel pins are integral in securing parts that must endure high stress and temperature variations, contributing to the overall safety and functionality of aerospace vehicles.

- Electronics: As electronic devices shrink in size and grow in complexity, the need for precise component placement becomes more critical. ISO 8735 standards facilitate the miniaturization of devices while ensuring reliability and performance through consistent component alignment.

- Construction and Machinery: Heavy machinery and construction equipment require robust parts that can handle heavy loads and continuous operation. Dowel pins specified by ISO 8735 ensure that these machines maintain structural integrity and operational reliability.

Advantages of Following ISO 8735 – 5×20 – A-C1 Entl.

Adhering to offers numerous advantages:

- Consistency: Ensures uniformity in production across different locations and times.

- Interchangeability: Allows for the easy replacement and assembly of parts, which is vital for maintenance and repair.

- Quality Assurance: Reduces the likelihood of component failure due to mismatch or poor fit.

- Cost-Efficiency: Minimizes waste and reduces the cost associated with trial and error in custom fitting.

Conclusion

It standard is more than just a set of dimensions for dowel pins; it is a crucial facilitator of quality, efficiency, and reliability in modern manufacturing processes. By standardizing critical components, ISO 8735 not only enhances product quality but also contributes to the safety and longevity of mechanical assemblies across various industries. As technology evolves and manufacturing demands become more complex, the role of such standards will only grow in importance, making compliance not just beneficial but essential for success in the global marketplace.